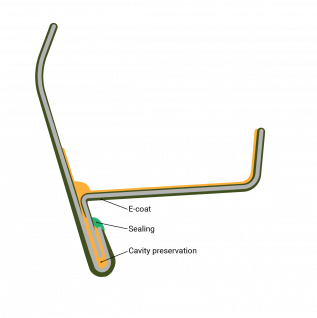

Corrosion protection in the cavity

Cavity structures of vehicle bodies form efficient constructions with high stiffness and crash protection relevance and therefore they must be protected against corrosion, especially in the presence of moisture.

Challenge

- During the cathodic dip coating (e-coat) process, incomplete coating may occur in sheet metal doublings (folds, gaps, welding spots, etc.)

- Movements such as torsion, vibration and oscillation of the bodywork can further damage the e-coat and hard coatings

- Moisture and salt combine in the cavity and then lead to crash-relevant corrosion in damaged areas

Solution

- Creation of a barrier between water and base material (barrier effect) through wax-based cavity coating with good creep ability

- Known as cavity protection

- The optimal material distribution is ensured by simulating the application.

- The waxes are air-drying and exhibit high long-term flexibility.

Sealed gap in the cavity

Sealed gap in the cavity

Benefit

- High safety due to flexible long-term corrosion protection

- Energy- and cost-efficient solution

- Reduction of costs in the development process through simulation of the material application

Sealed gap in the absence of KTL

Sealed gap of incomplete cathodic dip coating